Environmental Monitoring

Sample preparation for detection of heavy metal pollution in soil

Heavy metal pollution of the soil refers to the phenomenon that due to human activities of adding metals to the soil, the heavy metals in the soil are significantly higher than the original content, and the ecological environment quality is deteriorated.

Heavy metal hazards: affect the growth of plant roots and leaves, and damage the human nervous system, immune system, skeletal system, etc.

Characteristics of soil heavy metal pollution

- Heavy metals cannot be degraded by microorganisms and are long-term and potential pollutants in the environment;

- Due to the adsorption of soil colloids and particulate, it exists in the soil for a long time, and the concentration is mostly in a vertically decreasing distribution;

- Oil heavy metals can be bio-accumulated through the food chain, resulting in bio-magnification;

- The forms of heavy metals are different, and their activity and toxicity are different. Conditions such as soil pH, Eh, particulate matter, and organic matter content have a profound impact on its migration and transformation in soil;

As a major substance in soil pollution, heavy metals have always been a "stumbling block" to agricultural development. The heavy metals in soil are passed through the food chain and will eventually threaten human health. Industrial activities and human activities inevitably produce waste gas, waste, and wastewater, which contribute to the accumulation of heavy metals in soil to a certain extent. Soil heavy metal detection is getting more and more attention from people.

Which elements need to be detected in soil heavy metal monitoring? There are many heavy metal elements, but when it comes to environmental pollution, heavy metals that are easily enriched and harmful to the human body are mainly arsenic (As), cobalt (Co), chromium (Cr), copper (Cu), manganese (Mn), nickel (Ni) ), lead (Pb), titanium (Ti), vanadium (V), zinc (Zn), etc. In most cases, soil heavy metal detection is based on the content and distribution of these elements. The detection of heavy metals in the soil has an important reference value for analysis of the current state of soil pollution and the assessment of environmental pollution conditions. It is of positive significance to plan urban development, layout industrial and agricultural areas, and plan soil remediation schemes through the data obtained from the detection of heavy metals in the soil. Of course, soil heavy metal detection can also effectively deter polluting companies.

Sample preparation for soil heavy metal detection:

The soil samples obtained from the field need to be air-dried, ground, sieved, mixed, bottled and any other preparation process in the laboratory.

Sample coarse grinding: Pour the air-dried sample on the plexiglass plate in the sample grinding room, beat it with a wooden hammer, and use a wooden roller, wooden stick, or plexiglass stick to crush it again. Pick out impurities, mix well, take the crushed sample by quartering method, and pass it through a nylon sieve with an aperture of 0.25 mm (60 mesh). All the sieved samples are placed on the colorless polyethylene film and mixed thoroughly and evenly. Then use the quartering method to take two parts of them. One for sample storage, and the other one for sample fine grinding. The coarsely ground sample can be directly used for the analysis of soil pH, cation exchange capacity, and element effective content.

Sample fine grinding: The sample used for fine grinding is divided into four parts by the quartering method. One part is ground to 0.15mm (100 mesh) for AAS or ICP soil metal element analysis, and another part is ground to 0.075mm (200 mesh) for XRF fluorescence analysis of heavy metal elements.

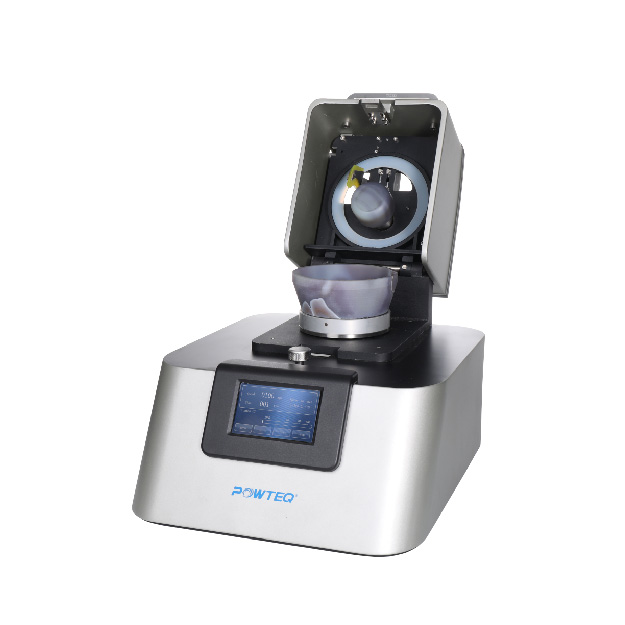

For fine grinding, planetary ball mill BM40/BM6pro, mortar grinder MG200 and disk mill DP100 can be used. For different soil samples and different application needs, select the corresponding instrument.

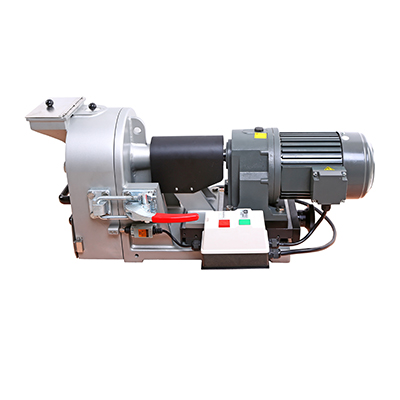

The DP50 soil mill developed by POWTEQ’s technicians with of decades industry experience is a specially designed instrument for soil preparation. It has fast grinding speed and high efficiency, with the finest reaching 75 microns in 3 minutes. By adjusting the gap between grinding discs, samples of different fineness can be achieved. There are few residues in the grinding chamber, which facilitates the processing of multiple batches of samples.

Soil mill DP50 is a fine grinding instrument. Not like other vertical disc designed mills in the market, its discs are stacked up and down in level, and size reduction under 75 microns for mid-hard and brittle samples can be achieved very fast. The reduction taken placed in a fixed mill disc and a moving mill disc. Easy handling, efficient milling, and less residual in the mill chamber make DP50 a favorable choice for large batches of environmental soil tests.

Typical samples

Soil, building material, nuclear ore, cement, concrete, cinder, coke, glass, porcelain, minerals, refractory clay, granite, monohydrallite, etc.

Working principle

The comminution effects are generated by the pressure and friction forces caused by a moving disc rotating against a fixed disc right below. The sample enters the mill chamber from the center of the discs, it would be pre-crushed there and then moves to the outer regions of mill discs by centrifugal force to be finer ground.The reduced particles fall into the collecting pan through the milling discs’ outer regions after milling, so the milling discs are clean and the sample collected.

Characteristics

- By means of adjusting the discs gap width precisely to achieve a reproducible grinding result;

- Preliminary grinding and fine grinding both can be done;

- Mill chamber worked with hinge design, easy to clean;

- Long use time of milling discs;

- Various materials of discs for contamination-free grinding;

- Dust-proof design.

|

Technical specifications |

|

|

Feed size |

<2mm |

|

Final fineness |

<75 um(95%) |

|

Rotate speed |

800rpm |

|

Collecting pan volume |

2 L |

|

Grinding sets material |

Hardened steel, agate, zirconium oxide, sintered aluminum, tungsten carbide |

|

Grinding gap width adjusts the range |

0-20mm |

|

Rated power |

550W |

|

Power supply |

220V, 50Hz |