Solid Waste

Powteq: Sample Preparation Technologies for Plastics

Recently, a study published in Environment International, a leading journal in the field of environmental science, revealed that scientists have found microplastics in human blood for the first time, further raising concerns about the long-term effects of microplastics on human health.

However, due to the physical properties of plastic samples and chemical components of the differences and specificity of different types of plastic samples, in the sample pretreatment needs to be treated differently, so for the grinding of plastic samples, the selection of grinding instrument is particularly important.

Selection I: Micro Ball Mill GT300

Micro Ball Mill GT300 is suitable for grinding plastic granular samples, which needs to be pre-treated with liquid nitrogen before grinding.

Product features

- GT300 has two grinding stations;

- Transparent window on the top cover allows the user to view the grinding situation at any time;

- Usually, it takes 3 minutes to grind a plastic sample.

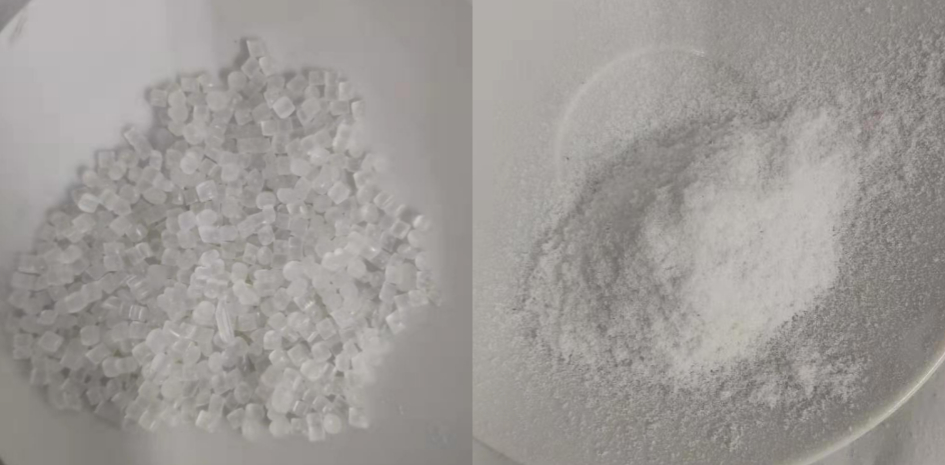

Grinding Case-Plastic granules

Sample material:

Samples are easily softened by heat and need to be frozen with liquid nitrogen for 6 minutes.

Experiment procedure:

- Take a small amount of sample into a 50 ml grinding jar.

- Immerse the grinding jar with sample into liquid nitrogen for 6 minutes.

- Wear protective gloves, install the grinding jars which have soaked in liquid nitrogen on the grinding platform.

- Cover the instrument, set the parameters and start the instrument.

Experiment configuration:

- Stainless steel grinding jar, 50 ml

- Grinding ball: 1 piece of stainless-steelgrinding ball of 25 mm

- Rotation speed: 1800rpm

- Experiment result: 97% ≤ 500 μm

- Grinding time: 3 minutes

Micro Ball Mill GT300 is an economical mill and is the first choice for laboratories that do not has high requirements for batch quantity.

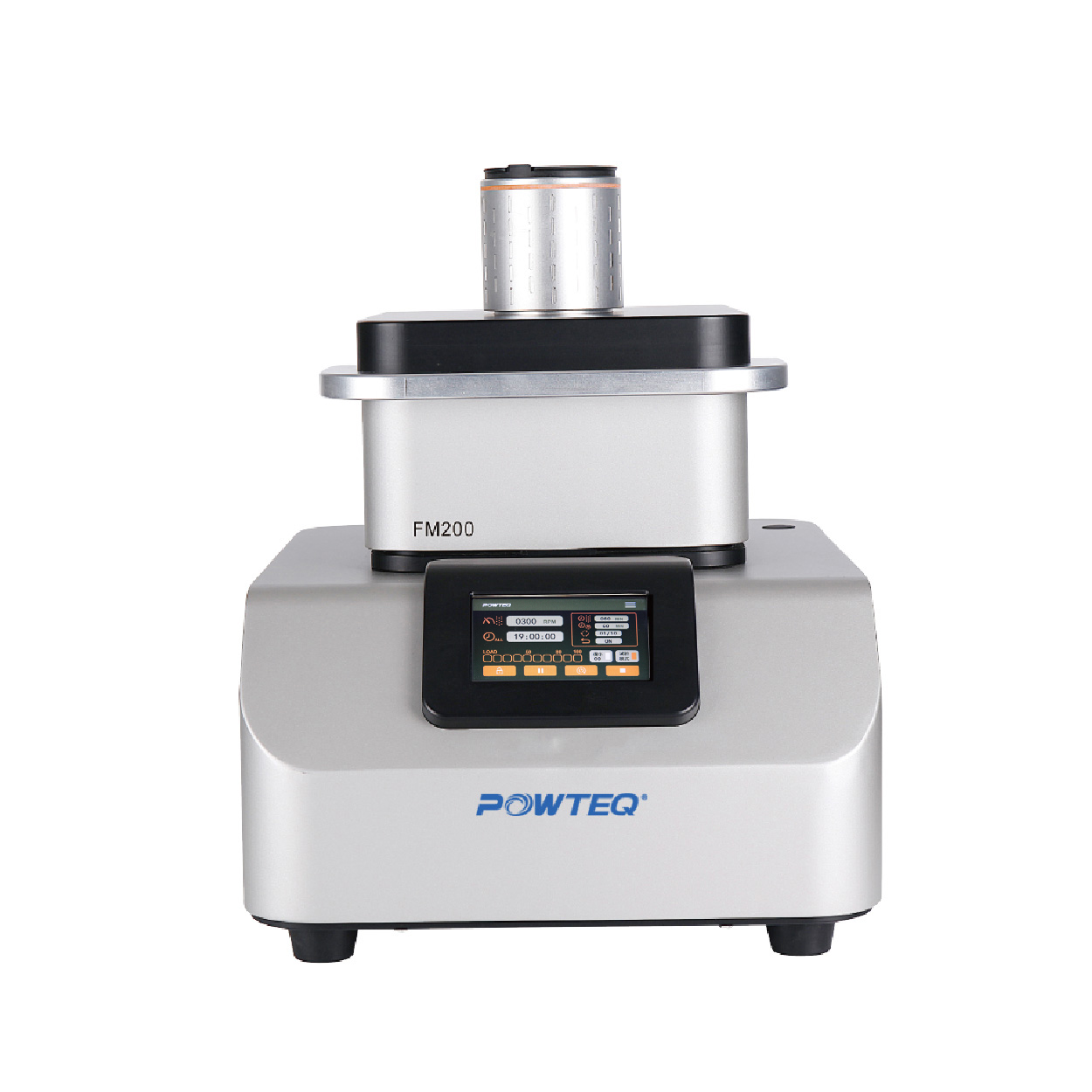

Selection II: Ultra Centrifugal Mill FM200

The Ultra Centrifugal Mill FM200 is suitable for grinding plastic granules and fragment type samples, which need to be pretreated with liquid nitrogen to make them brittle before grinding.

Product features

- FM200 is of huge speed range and in and out of the grinding mode;

- The final fineness of the sample can be determined by selecting different apertures of the ring sieve size. There are more reinforced screen frames to strengthen the stability of the ring sieve;

- It can be connected to the cyclone separator, so that the sample can be cooled by airflow, and to ensure that the grinding process is fast and effective;

- The cyclone separator can be used with 250 ml, 500 ml or 1 liter sample bottles to facilitate the collection of large sample volumes;

- Two stage rotor-ring sieve system to realize quickly grinding.

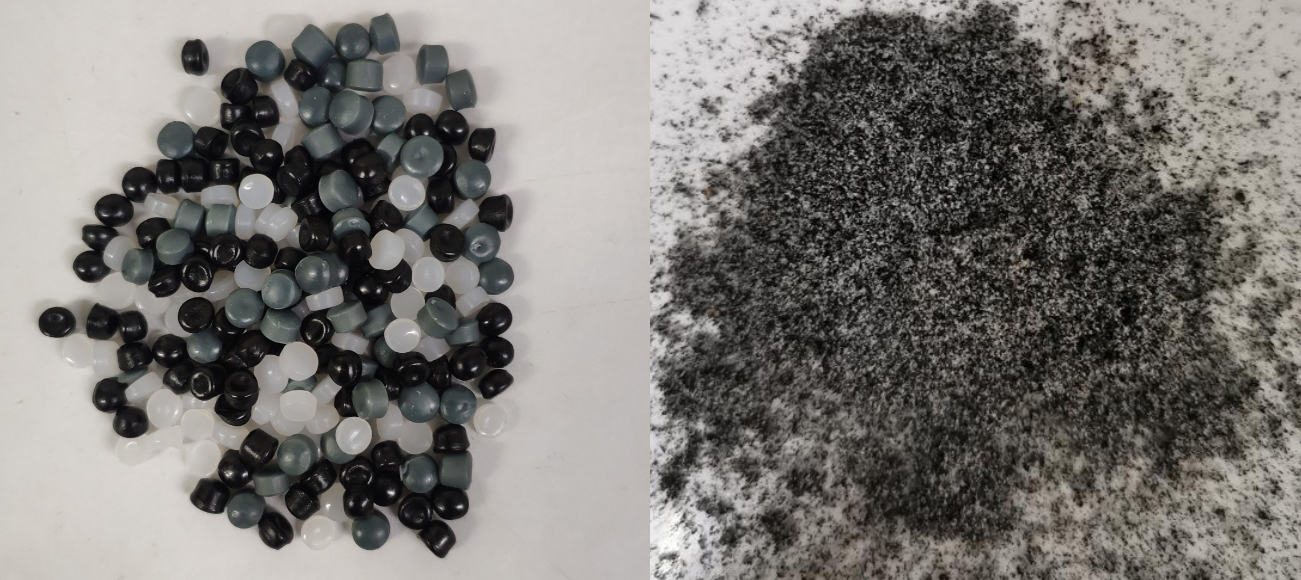

Grinding Case- plastic pellet

Sample material:

- The sample is PP plastic pellet.

- They are of strong toughness, not easy to grind, and need to be placed in liquid nitrogen frozen for 2 minutes.

Experiment process:

- Put the sample directly into the liquid nitrogen and immerse them for 2 minutes;

- Start the instrument and set the parameters.

- Add the sample into the instrument at a uniform speed.

Experiment configuration:

- Stainless steel 12 teeth rotor

- 0.5mm reinforced sieve ring

- Rotation speed: 18000rpm

- Experiment result: 97% ≤ 500 μm

- Grinding time: immediate in and out

Because of its high grinding efficiency and suitable for a wide range of samples, this Ultra-Centrifugal Mill FM200 is also one of the most selected equipment in many laboratories.

Selection III: CryoGrinder LM200

CryoGrinder LM200 is suitable for grinding plastic samples which are temperature sensitive and easy to be softened. It is the first choice for temperature sensitive samples.

Product features

- It can avoid the contact and danger of manual operation: the whole grinding process is always carried out in liquid nitrogen environment (-196℃);

- With liquid nitrogen automatic refilling system, it automatically replenishes the liquid nitrogen consumed in the process of freezing and grinding of samples;

- When the lid of the instrument is in the open state, the instrument cannotbe started;

- In order to ensure a better grinding effect, it is able to choose the appropriate size of grinding jar according to the batch quantity;

- It usually takes about 8 minutes to process a plastic sample.

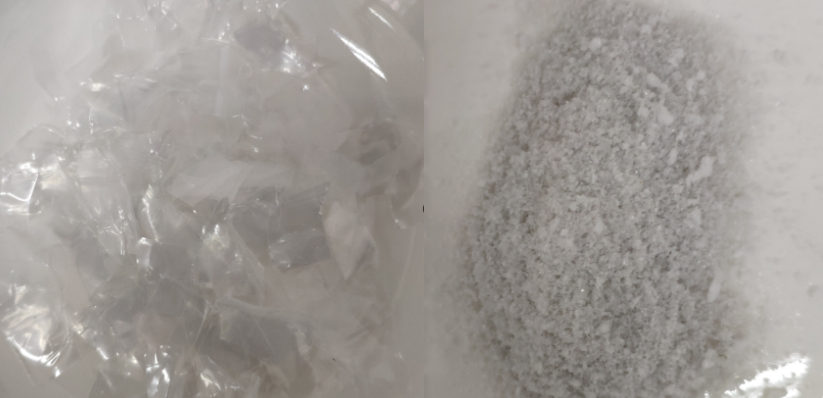

Grinding Case-self-sealing bag

Sample material:

- The self-sealing bag material is polyethylene, which is of poor heat resistance and easy to be softened;

- The sample is of strong toughness, not easy to grind, so the grinding process needs to control the amount of sample;

- The sample particle size will gradually become smaller with the extension of the grinding time.

Experiment process:

- Put the sample into 200 ml grinding jar;

- Place the grinding jar with the sample into the grinding chamber of the CryoGrinder;

- Start the instrument and set the parameters;

- Remove the grinding jar after grinding, and use the jar opening aid to open it.

Experiment configuration:

- Accessories selection: 200ml PC grinding jar

- Parameter setting: 15Hz, pre-freezing for 5min, grinding for 3min, pause for 3min, cycle for 4 times.

- Grinding result: 90% <500 μm

Summary:

Each of the three instruments has its own characteristics, Micro Ball Mill GT300 is economical; the Ultra Centrifugal Mill FM200 is highly efficient; and CryoGrinder LM200 is convenient and highly automated. In the laboratory testing and industrial production, there are many different plastic raw materials and plastic products, we recommend you to select a suitable instrument from the actual needs, the sample material and requirement for processing capacity.

Powteq: Make sample preparation more easier and efficient!