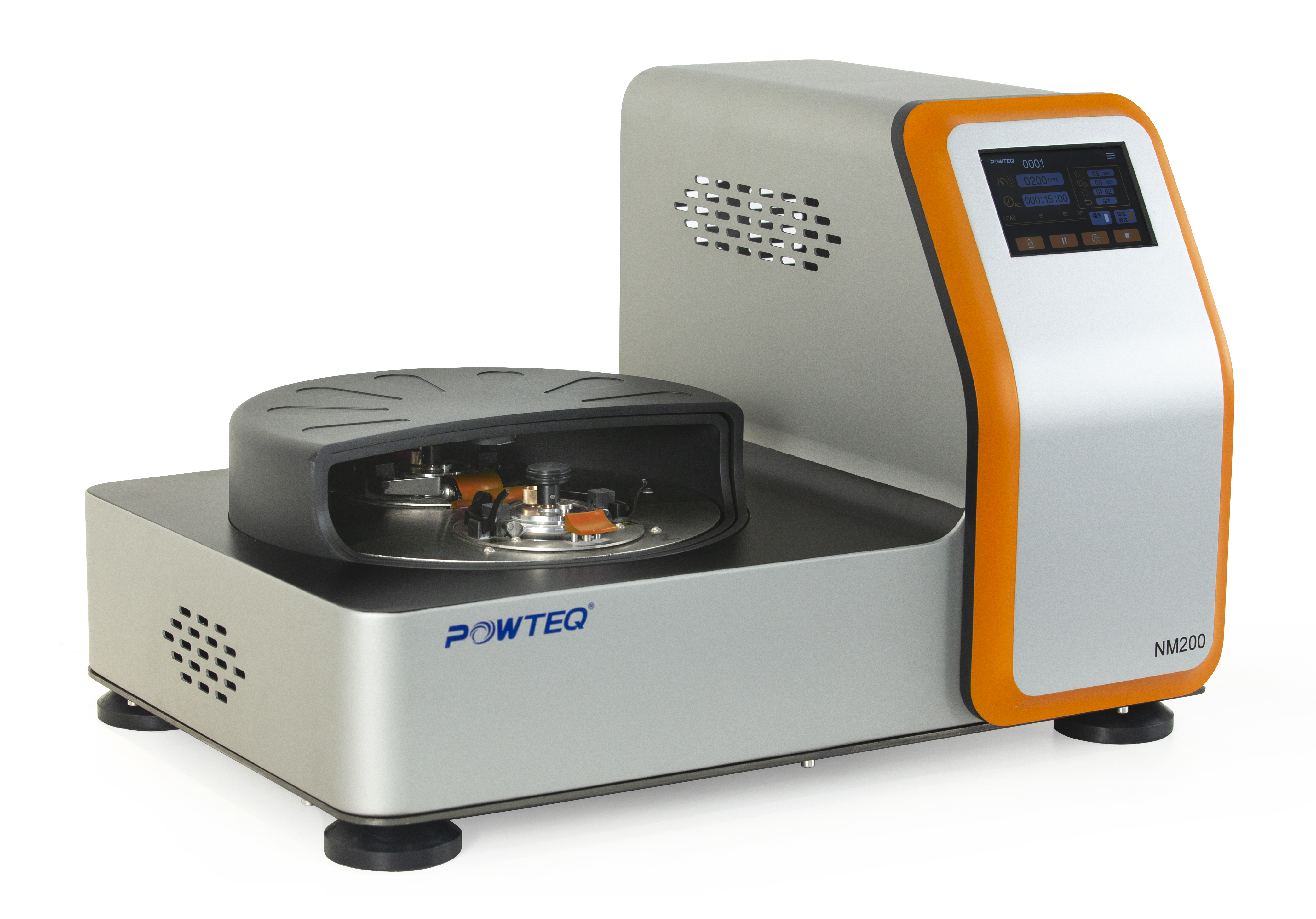

High performance mini Planetary Ball Mill NM200

Speed of sun wheel: 100-1100 rpm

Speed of jars: 200-2200 rpm

Final fineness: <0.1μm (depending on sample characters)

High performance mini Planetary Ball Mill NM200 has a wide range of applications and is ideal for lossless grinding of hard, medium hard and brittle materials up to the final fineness of 100 nm. Besides dry grinding, size reduction can also be done in suspension or inert gases depending on the desired final fineness. In addition to crushing, you can also use NM200 to mix and homogenize emulsion and paste samples or apply them to mechanical activation and alloying materials research.

|

Application |

Sample types: soft, hard, brittle, fibrous

Application areas: engineering/electronics, building materials, agriculture, pharmaceuticals, chemical synthetic materials, geological/metallurgy, environment/resources recycling, glass/ceramics, biological and other fields.

Typical samples: Plant materials, cement slag, concrete, compost, coatings and paints, charcoal, hair, catalysts, chemicals, alloys, carbonized fibers, paper, fiber products, cellulose, seeds, clay minerals, coke, coal, glass, electronics waste, minerals, ores, limestone, iron ore, bentonite, gypsum, quartz, kaolin, bone, metal oxides, ceramics, polymers, pigments, etc

Special application: In addition to the classical mixing and grinding process, NM200 can also meet the technical requirements of colloid grinding, and its high energy input can meet the requirements of mechanical alloys preparation.

|

Working Principle |

The grinding jar is arranged on the sun wheel of the planetary ball mill off-centered. The rotating direction of the sun wheel is opposite to that of the grinding jar in a ratio of 1:-2. The velocity difference between the ball and the grinding jar creates an interaction force of friction and impact, which releases high dynamic energies that act on the particle sample so as to quickly produce highly uniformed and very fine particle.

|

Features and advantages |

- High reliability and repeatability.

- Processing 2 samples at the same time.

- High safety performance, the grinding chamber lid can’t be opened during grinding.

- Automatic positioning and locking of the jars, no need for manual operation.

- Jar balance detection, reliable safety protection.

- With air cooling system, effectively reduces the heat gathered inside jars.

- High friction and energy input, a good option for nanomaterials and alloying material preparation.

- Pressure and temperature measuring system (PTM) helps to achieve better grinding and analysis results.

- Multiple materials and specifications of the grinding jar are optional.

- O ring effectively seals dust and is suitable for wet grinding.

-

LED 7-inch screen, easy parameter setting and display.

-

User-friendly interface, simple operation.

| Technical Data |

|

Feed size |

<5mm |

Grinding process |

dry/wet |

|

Final fineness |

<0.1μm (depending on sample) |

Jar material |

Zirconium oxide, stainless steel, tungsten carbide |

|

Speed of sun wheel |

100-1100 rpm |

Jar volume |

20/45/80ml |

|

Number of stations |

2 |

Centrifugal acceleration |

95g |

|

Effective dia. of the sun wheel |

140mm |

Rated power |

1200W |

|

Sample quantity |

2-60ml |

Voltage |

220V,50/60Hz |

* Information on this site is provided for information purposes only and the contents hereof are subject to change without notice.

| Item No. | Description |

| 24.912.0001 | Mini Planetary Ball Mill NM200, 220V, 50/60Hz |

| Grinding jar | |

| Stainless steel | |

| 01.912.0001 | 20ml |

| 01.912.0002 | 45ml |

| 01.912.0003 | 80ml |

| Zirconium oxide | |

| 01.912.0004 | 20ml |

| 01.912.0005 | 45ml |

| 01.912.0006 | 80ml |

| Tungsten carbide | |

| 01.912.0007 | 20ml |

| 01.912.0008 | 45ml |

| 01.912.0009 | 80ml |

| Accessories | |

| 02.912.0001 | Gasket, silicone |

| 02.912.0002 | Gasket, fluorine rubber |

| 02.912.0003 | Aeration lid for 20/45/80ml stainless steel jar |

| 02.912.0004 | Aeration lid for 20/45/80ml zirconium oxide jar |

| 02.912.0005 | Aeration lid for 20/45/80ml tungsten carbide jar |